Power Management ICs (PMICs) are Showing Up in Unexpected Places

Where there’s power, there’s a need for some level of power monitoring and management. Of course, that’s not news to any designer with real-world experience. What’s interesting is how the proliferation of electronics in general—and smart electronics in particular—has also expanded the need for tightly focused power management ICs (PMICs).

This is happening due to the spread of processors, firmware, and motion control into less-obvious application niches. The need for PMICs is reaching into the “nooks and crannies” of automobiles too, as designers increasingly use processor-based interfaces and controls to enable the rapid realization of that widely cited phrase, “Software is eating the world.”

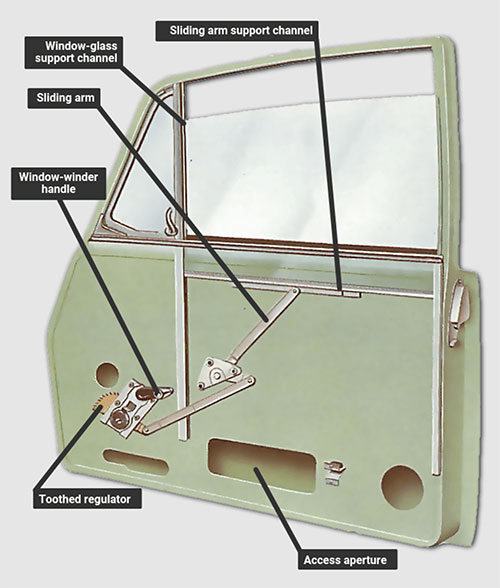

Consider the humble car window. Until about 50 years ago, these windows were manually operated via a mechanical linkage actuated by a simple hand-powered rotary crank; each occupant of the car had to manage their own window using their “arm” as the power source (Figure 1).

Figure 1: The manual, crank-operated car window was the only option for many years. (Image source: How a Car Works)

Figure 1: The manual, crank-operated car window was the only option for many years. (Image source: How a Car Works)

You could buy a plain replacement crank in case yours broke at any auto supply store, and decorative aftermarket cranks were also popular (Figure 2).

Figure 2: Plain replacement cranks, as well as decorative versions, were standard auto supply store items back when windows were crank operated. (Image source: Joom SIA)

Figure 2: Plain replacement cranks, as well as decorative versions, were standard auto supply store items back when windows were crank operated. (Image source: Joom SIA)

Power windows were first introduced in the 1940s, but used an electrically controlled hydraulic-powered system as small electric motor technology (size, power, and control) was not advanced enough to allow them to be embedded into the door. In the 1960s, though, the Cadillac Fleetwood came standard with windows powered by electric motors, and within about a decade, power windows were a standard feature on most cars, a fairly quick rate of mass-market adoption.

Two basic mechanisms were used for what is formally termed a window regulator: the Ford cable-type regulator (Figure 3), and the Toyota gear-drive-type window regulator (Figure 4).

Figure 3: The Ford power mechanism for the window regulator used a cable and sliding assembly. (Image source: Samarins)

Figure 3: The Ford power mechanism for the window regulator used a cable and sliding assembly. (Image source: Samarins)

Figure 4: The Toyota power mechanism was based on a geared “scissor” arrangement. (Image source: Samarins)

Figure 4: The Toyota power mechanism was based on a geared “scissor” arrangement. (Image source: Samarins)

Regardless of which mechanical design was used, both had one aspect in common. Unregulated 12 volt DC power went directly from the car battery to the window motors via the individual driver/passenger control switches. As a result, incorporating this “convenience feature” into the car added to the ever-increasing burden of thicker cable harnesses and the challenges of routing them around the vehicle.

Fortunately, the migration to using low-speed networks such as the Controller Area Network (CAN) bus or Local Interconnect Network (LIN Bus) within the car has reduced the cable harness difficulty. Now, 12 volt power goes only to the regulator motor in the door, while a networked switch with thinner cabling can signal the motor controller to raise/lower/stop the window. Within a few years, what started out as a basic network-friendly window-motor controller evolved into a smart, processor-based controller with advanced performance capabilities.

As with most improvements, there are other “ripple effects.” The enhanced window network interface/motor controller IC needs more sophisticated power management and regulation, and that’s where a PMIC comes into the picture. This IC needs to monitor and manage the DC power, and it needs to self-test to ensure that any excessive variations in power or other problems are detected promptly, and appropriate action is taken before there is any damage to the motor or associated components.

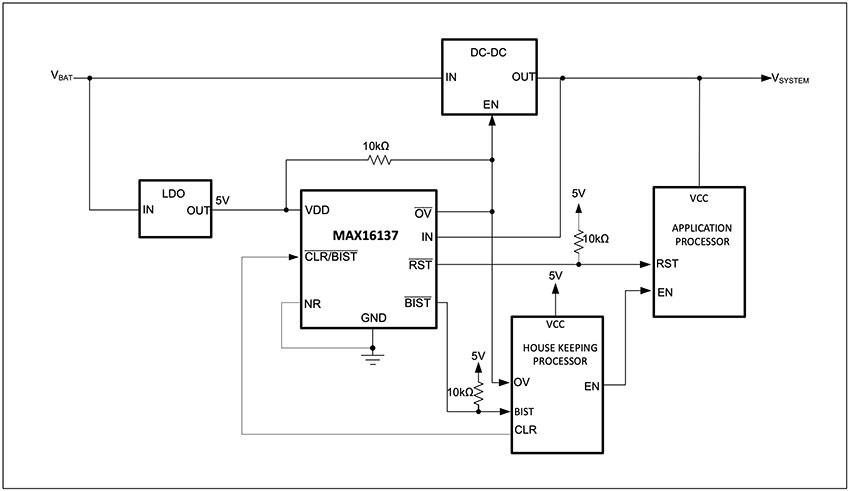

That’s the function of the MAX16137 from Maxim Integrated. This low-voltage, highly accurate supervisory circuit monitors a single system supply voltage rail for undervoltage and overvoltage faults, specifically targeting the needs of automobile power windows and their interface/controller ICs, although it can be used for similar monitoring elsewhere in the vehicle (Figure 5).

Figure 5: The MAX16137 power supervisory IC works in conjunction with the motor control manager to monitor the power rail. (Image source: Maxim Integrated)

Figure 5: The MAX16137 power supervisory IC works in conjunction with the motor control manager to monitor the power rail. (Image source: Maxim Integrated)

When the monitored supply voltage drops below the undervoltage threshold or goes above the overvoltage threshold, the IC’s reset output goes low; this output returns to “normal” after a reset timeout period once the supply voltage returns to within the undervoltage and overvoltage threshold window. The 1% accuracy provides supervisory consistency, while the overvoltage/undervoltage windowing value can be factory set at ±4 percent to ±11 percent of the target voltage.

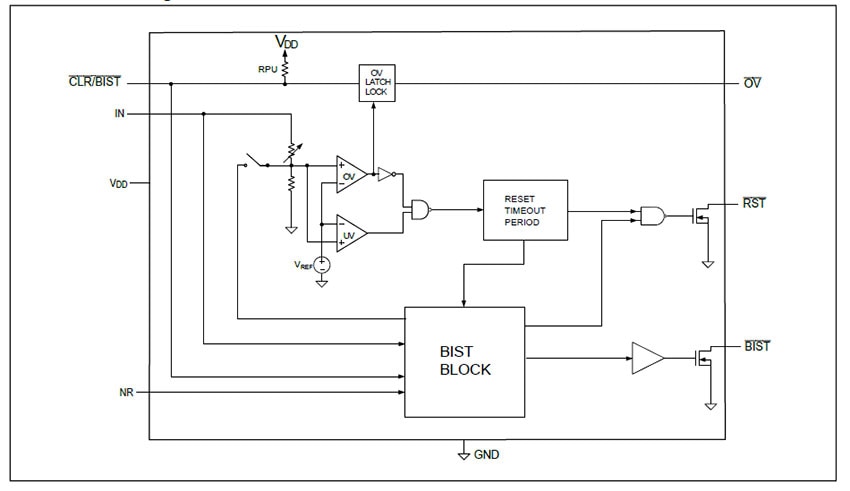

That’s just one role of the MAX16137. In addition, its unique built-in-self-test (BIST) diagnostic capability monitors the health of the internal reset circuit during power-up (Figure 6). If the BIST fails, the MAX16137 pulls its BIST output low to alert the associated processor.

Figure 6: Along with tight power management, the MAX16137 has a BIST block that monitors the health of the internal reset circuit during power up. (Image source: Maxim Integrated Products)

Figure 6: Along with tight power management, the MAX16137 has a BIST block that monitors the health of the internal reset circuit during power up. (Image source: Maxim Integrated Products)

Space in car doors is at a premium, so the 8-lead, 2 × 2 millimeter (mm) package of the MAX16137 is an appropriate fit, and it is, of course, AEC-Q100 qualified. The advanced diagnostics at the chip level help developers meet system-level functional safety requirements with significantly reduced board space.

Conclusion

If a design has physically dispersed processors and smart controllers, especially in an electrically harsh environment such as a car, it’s important to have localized PMICs to ensure that power issues and glitches don’t cause transient or permanent system malfunctions. Users expect consistent, reliable performance and don’t want to see a “check engine” light come on for problems associated with the car’s many scattered processors/controllers. This is especially the case when many of these scattered nodes are not critical to the basic car functions. ICs such as the MAX16137 provide a solution to ensure reliability even under extreme conditions.

References:

1. GoMechanic, “Power Windows In Cars and the Interesting History Behind Them”

https://gomechanic.in/blog/history-behind-power-windows/

2. Wikipedia, “Power Window”

https://en.wikipedia.org/wiki/Power_window

3. Samarins, “Power window regulator, window motor: problems, testing, replacement”

Have questions or comments? Continue the conversation on TechForum, Digi-Key's online community and technical resource.

Visit TechForum